One-stop electronic product customization, powered by an outstanding R & D team!

R&D Team Introduction

At Shenzhen MHC, our Research and Development (R&D) center is the heartbeat of innovation, driving the creation of cutting-edge electronic products. Our dedicated team of 15 professionals brings diverse expertise and passion to every project.

Team Composition:

· Product Software and Hardware Development Experts (7): These specialists form the technical backbone of our products, focusing on robust software architecture and efficient hardware integration.

· Appearance and Structural Designers (2): They combine aesthetics with structural integrity, ensuring our products,such as surveillance camera systems, wireless alarms, and other products are visually appealing and durable.

· Project Managers (2): Responsible for coordinating development efforts for products such as 4K underwater cameras and hunting trail cameras, they ensure projects are delivered with precision and timeliness.

· Market Analysis and Research Expert (1): Guides product functionalities, including ozone generators and driveway alarms, based on comprehensive market analysis, aligning our offerings with consumer needs and trends.

· Product Certification Specialist (1): Ensures compliance with regulatory standards and certifications, guaranteeing that our 4G hunting cameras and other products meet global expectations.

· Technicians (2): Conduct rigorous performance testing on long-range wireless alarms, underwater cameras, and other products to maintain our high standards and meet customer expectations consistently.

Collaboration and Market Integration:

Through over a decade in the electronics industry, Shenzhen MHC has cultivated strong partnerships with professional teams in the United States and Hong Kong. These collaborations enhance our ability to develop custom consumer electronics and custom outdoor electronic products by leveraging technological advancements and market insights. By fostering joint development, introducing new technologies, and co-developing products, we accelerate the transformation of R&D outcomes into tangible innovations.

Our R&D advantages:

Our R&D process reflects our commitment to leading the electronics market. This customized product realization path includes:

Conceptualization and Market Analysis: Leverage our market research expertise to identify opportunities and define product concepts.

Design and Engineering: Our software and hardware experts, along with our appearance and structural designers, transform concepts into viable designs.

Project Management and Standardization: Our project managers and standards experts ensure that products meet not only our internal benchmarks, but also global standards.

Prototype Development and Testing: In-depth performance testing by our professional technicians verifies design and functionality, iterating until perfection.

Certification and Market Readiness: Obtain final certification, refine market strategy, and lay the foundation for product launch.

Release and Continuous Improvement: After launch, our team remains involved, collecting market feedback to continuously improve the product.

Project Procedures

At Shenzhen MHC, we follow a meticulous eight-step process to ensure the successful development and delivery of customized electronic products tailored to our customers' needs. At Shenzhen MHC, our structured project procedures ensure efficiency, quality, and customer satisfaction throughout every stage of product development and delivery.

1Demand Planning

Customers provide their product ideas, drawings, or samples. We engage in detailed discussions to understand their requirements fully. Our team evaluates the feasibility of the concept based on our expertise and experience.

2Formulate Project Plan

Shenzhen MHC R&D team confirms product specifications and applications based on customer needs and application scenarios, and creates and optimizes a set of feasible solutions.

3Evaluate Feasibility Plan

Following initial discussions, we provide customers with comprehensive quotations based on the discussed product specifications and development complexity. Upon agreement, both parties sign a contract and the customer pays a deposit to initiate the project.

4Project Design

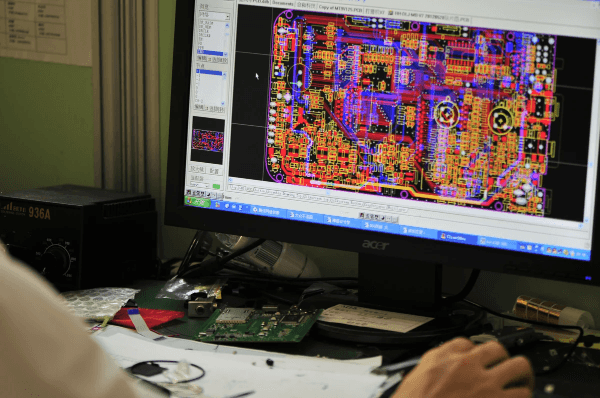

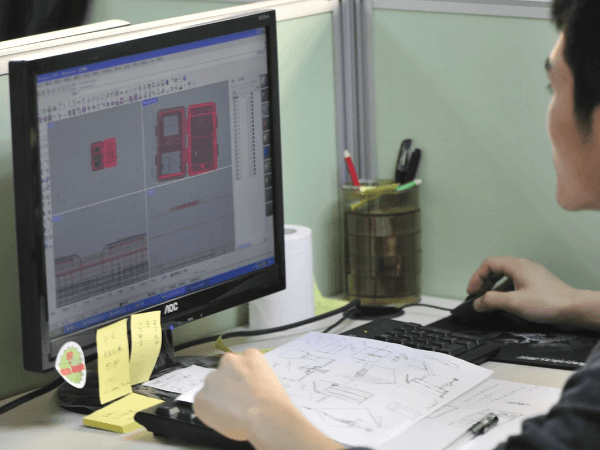

The R&D project commences, encompassing industrial design, including appearance and structural design, industrial design prototyping, PCB schematic design, PCB layout, PCB manufacturing, SMT patch assembly, mold development, software debugging, and structural assembly. Throughout this phase, we maintain transparent communication with customers, providing regular updates on project progress.

5Sample Testing

Upon completion of mold design, production, and debugging, we proceed to sample production. We conduct rigorous testing on samples and provide customers with comprehensive reports, including photos and videos for visual confirmation. Samples are sent to customers for final approval and signature.

6Trial Production & Mass Production

Following customer approval of samples, production commences. Customers arrange payment, and we initiate material procurement for trial production and subsequent mass production based on approved samples.

7Pre-shipment inspection

After completing mass production, we conduct thorough pre-shipment inspections. Customers may request samples for double-checking or opt to have a third-party inspection at our facility to ensure product quality and compliance.

8Delivery

Upon successful inspection, we arrange transportation for timely delivery of the goods to our customers, ensuring smooth logistics and fulfillment.

Main Factory:

Add:4th Fl., Bldg. 1, No. 7 Zhidun Ln., Qingshui Rd., Longxi Cmty., Longgang St., Longgang Dist., Shenzhen, China

We are committed to delivering high product quality, ensuring cost efficiency, and fulfilling our delivery promises to our valued customers.